Case background:

A 3D printing equipment manufacturing enterprise in Hangzhou focuses on the research and application of high-end additive manufacturing technology, and its products are widely used in aerospace, medical equipment, precision manufacturing and other fields. Due to the extremely high requirements for the flatness, heat resistance, and mechanical properties of the printed substrate in 3D printing equipment, the company's technical demonstration determined that TC4 titanium alloy is the ideal substrate material. Later, they entrusted our company to deliver the finished product directly with the work and materials, and established a cooperative relationship with our company.

Solution:

As a professional titanium material supplier, our company provides qualified TC4 titanium alloy substrate materials and subsequent machining services to meet the needs of the enterprise. By utilizing our own experience and resources in the industry, we have provided customers with a one-stop solution, allowing them to have no worries about several components.

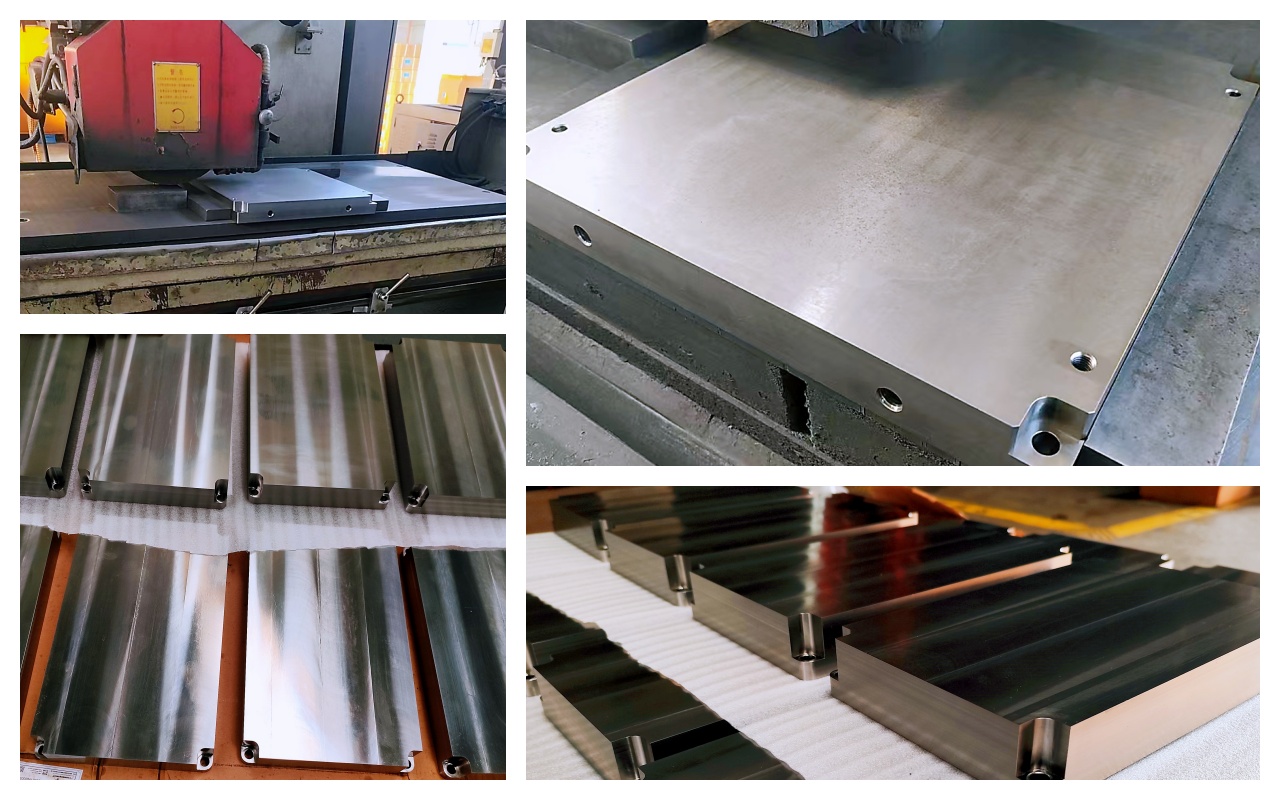

Material customization: Provide titanium substrates of different sizes and thicknesses according to the design requirements of 3D printing equipment, ensuring that their surface flatness and dimensional accuracy meet high-precision printing needs.

Surface treatment: Precision grinding and polishing of titanium substrates to ensure surface roughness below Ra0.8, meeting the process requirements for high-precision printing.

Technical support: Provide customers with proper protection, maintenance, and usage suggestions during the transportation of titanium substrates.

Quality assurance: All titanium substrates undergo strict chemical composition analysis and UT non-destructive testing.

Implementation effect:

By using the titanium substrate provided by our company, the enterprise has successfully improved the printing accuracy and stability of 3D printing equipment, especially in high-temperature printing environments. The titanium substrate exhibits excellent heat resistance and deformation resistance, significantly improving the printing yield. Customer feedback shows that the application of titanium substrates not only improves equipment performance, but also reduces material waste during the printing process, bringing significant economic benefits to enterprises.

Summary:

This cooperation fully demonstrates our company's professional capabilities and service level in the field of titanium material supply. In the future, we will continue to provide customers with high-quality titanium substrates and technical support, helping them achieve greater breakthroughs in the field of 3D printing equipment manufacturing.

An example of titanium material supply for an additive equipment manufacturing enterprise in Hangzhou-team-Baoji Cooperative Innovation Titanium Metal Co., Ltj

An example of titanium material supply for an additive equipment manufacturing enterprise in Hangzhou-team-Baoji Cooperative Innovation Titanium Metal Co., Ltj