Case background:

A reactor production enterprise in Suzhou focuses on the research and manufacturing of chemical reaction and mixing equipment, and its products are widely used in fields such as petrochemicals, pharmaceuticals, and food. Due to the high temperature, high pressure, and strong corrosive environment in which the reaction kettle operates, there are extremely high requirements for the corrosion resistance, strength, and stability of the materials. The company has established a cooperative relationship with our company when searching for a material that can meet its demanding working conditions.

Solution:

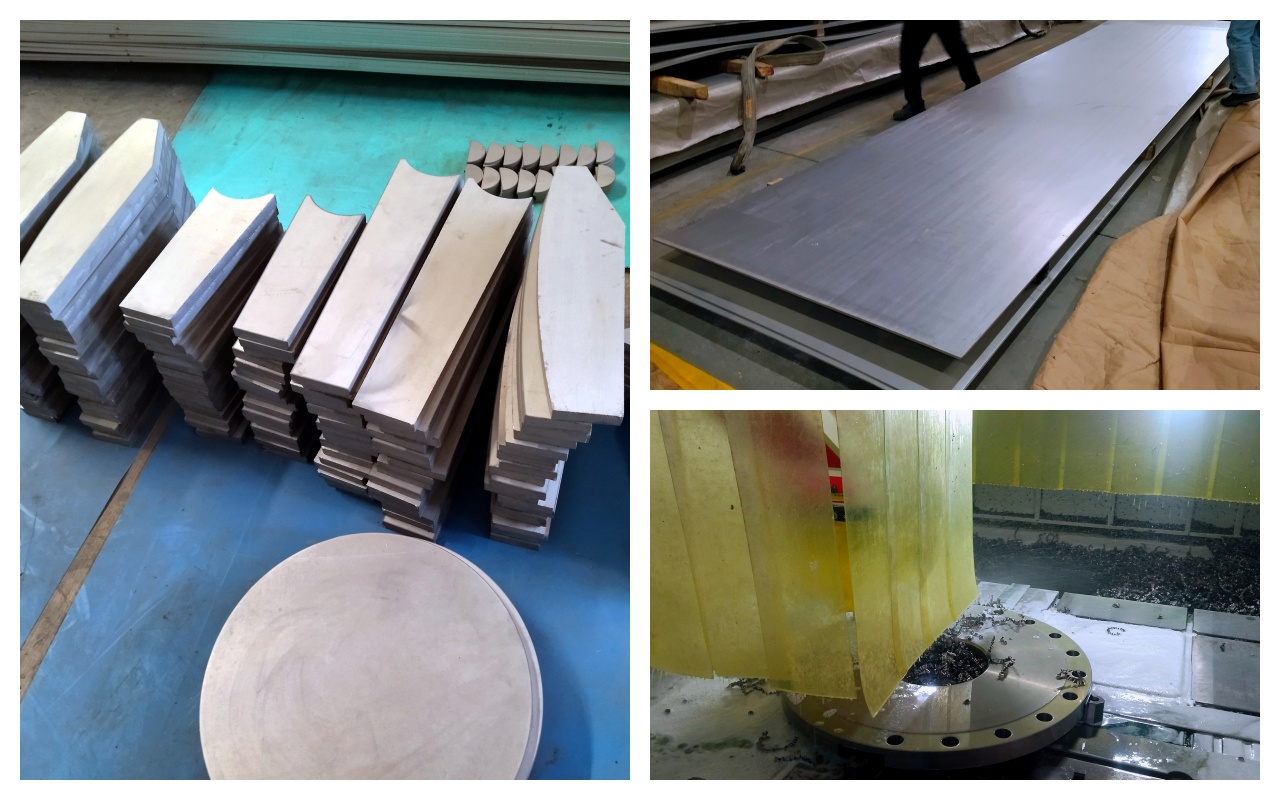

As a professional titanium material supplier, our company provides suitable titanium material grades such as TA2/TA10 (GR2/GR12) to meet the needs of the enterprise. Titanium material has become an ideal choice for the manufacturing of chemical reaction vessels due to its excellent corrosion resistance, high strength, and lightweight characteristics. We provide the following services based on the specific needs of our clients:

Material customization: According to the design requirements of the reaction vessel, different specifications of titanium plates, titanium pipes, and titanium forgings are provided to ensure that the material properties fully meet the equipment manufacturing standards.

Technical support: Provide customers with technical guidance on welding, processing, and surface treatment of titanium materials, helping them optimize production processes and improve product quality.

Quality assurance: All titanium materials undergo rigorous chemical composition analysis and mechanical property testing to ensure compliance with domestic and international standards such as GB/T, ASTM, ASME, etc.

Implementation effect:

By using the titanium material provided by our company, the enterprise has successfully manufactured multiple batches of high-performance chemical reaction vessels. The equipment exhibits excellent corrosion resistance and stability in strong acid, strong alkali, and high temperature and high pressure environments, significantly extending its service life. Customer feedback shows that the application of titanium materials not only enhances the market competitiveness of products, but also reduces equipment maintenance costs, bringing significant economic benefits to enterprises.

Summary:

This cooperation fully demonstrates our company's professional capabilities and service level in the field of titanium material supply. In the future, we will continue to provide customers with high-quality titanium materials and technical support, helping them achieve greater breakthroughs in the field of high-end chemical equipment manufacturing.

An example of titanium material supply cooperation between a chemical reactor equipment manufacturing enterprise in Suzhou-team-Baoji Cooperative Innovation Titanium Metal Co., Ltj

An example of titanium material supply cooperation between a chemical reactor equipment manufacturing enterprise in Suzhou-team-Baoji Cooperative Innovation Titanium Metal Co., Ltj